Structural Digital Twins: Reinventing How We Test and Trust Complex Designs and Advanced Material

Traditionally, certifying aircrafts and vehicles has relied on safety measures, historical data, and physical tests. This process is slow, careful, and often very cautious, for good reason, because people’s lives depend on these systems working safely under extreme conditions.

However, things are starting to change. We are now using new materials and manufacturing methods that are very different from traditional metals. These include custom composites, lattice structures, 3D printing, and generative design. These new techniques can offer better performance, but they come with a downside: unpredictable behavior and limited data when using traditional certification methods. This mismatch creates a bottleneck because innovation is advancing faster than the methods meant to ensure its safety.

At Autodesk Research, we are working on a new way forward through our investigation of performance-aided design: structural digital twins that create full mechanical property reconstruction based on a limited number of strain gauge sensors. These systems are more than digital copies. They are live, model-based representations of a physical object, fed continuously by sensor data and finite element physics simulations. They let us understand stress, strain, system-wide failures, and forces acting on the system during operation, extending far beyond the scope of traditional lab tests.

To put this to the test, we built an experiment based on a propeller boom arm from an Unmanned Aerial Vehicle (UAV). It’s a critical structural part: lightweight, load bearing, and exposed to a variety of forces during flight. Instead of flight-testing the whole vehicle, we set up a dedicated lab rig that mimics the loads experienced in operation. Think of it like a crash test dummy, but for structural intelligence. Our research progresses incrementally, starting with a boom made of aluminum, loaded under controlled static to dynamic, and then randomized conditions. Over time, we plan to test with increased complexity, testing a light-weight composite version of the propeller arm.

The foundation of our system is a python surrogate model built from Autodesk Nastran simulations. Running full finite element simulations in real time would be computationally expensive; instead, we precompute the linear elastic structural responses to a set of six-unit loads (one for each degree of freedom) and combine them with actual sensor readings.

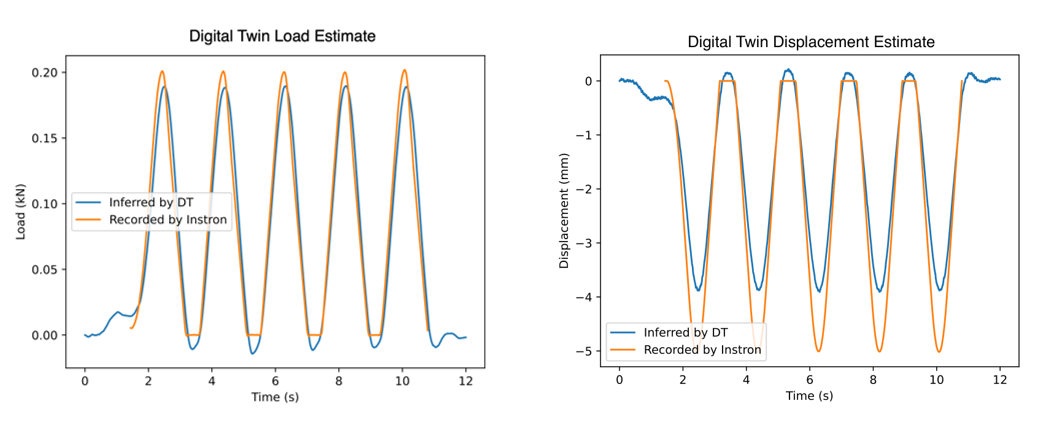

From here, the digital twin uses sparse strain measurements from sensors mounted on the physical boom and synthesizes the data with surrogate model data to reconstruct the full internal stress distribution in real time. For static loads, we solve a least of squares problem to estimate what forces must have caused the observed strain. For dynamic cases, we implement a technique known as Kalman Filter with Gaussian Process Latent Force Models, which allows us to infer time-varying, uncertain loads, like those you would expect in real flight. Unlike traditional CAD simulations, this digital twin learns, adapts, and continuously updates itself based on real-world data.

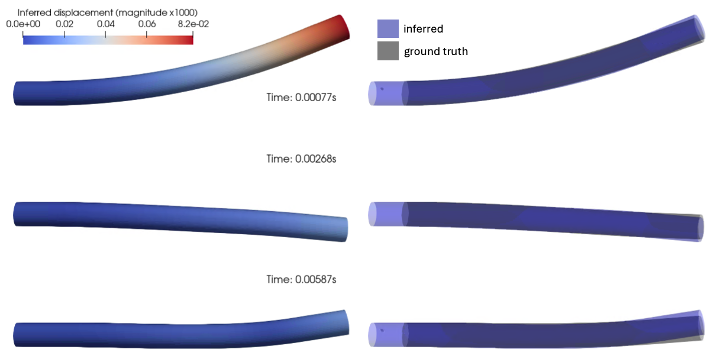

Deformed shapes of the boom arm at different time values based on inferred displacement field of the digital twin, assuming Autodesk Nastran as ground truth

Dynamic load digital twin inference (blue) compared to load and displacement results recorded on the Instron 6800 series universal testing machine (orange)

Traditional certification relies heavily on worst-case assumptions and historical testing data. That is a challenge when you are dealing with new materials or geometries because the data does not exist yet. Engineers are often required to overbuild, overspend, and conduct excessive testing to meet safety margins. A structural digital twin offers the potential to make informed prediction based on actual performance. This means lighter designs, faster development cycles, and potentially safer systems, because engineers no longer have to rely on guesswork, they are measuring and modeling continuously. This is especially powerful for composites and additive structures, where failure modes are often non-obvious or unintuitive. With a digital twin, engineers can detect anomalies early, estimate fatigue in real time, and tune future designs based on operational data.

This foundational research prototype serves as a powerful proof of concept when validating the design to testing data pipeline using Autodesk Fusion and Nastran, and scalability to other structural systems. Looking ahead, this could unlock faster, smarter, and more sustainable design workflows extending beyond UAVs to any structure that needs to perform under uncertainty. To learn more about this research and its methodology, you can read the paper “Towards Certification-Ready Designs: A Research Investigation of Digital Twins for High-Performance Engineering” or on the NAFEMS Website.

Get in touch

Have we piqued your interest? Get in touch if you’d like to learn more about Autodesk Research, our projects, people, and potential collaboration opportunities

Contact us