From CAD to Robotic Assembly

Fabrica began with a simple question: Can a robot take a CAD model of a multi‑part object and build it—end‑to‑end—in the real world, without hand‑crafted heuristics or human demonstrations?

At the 9th Conference on Robot Learning (CoRL 2025) in Seoul, our answer earned a Best Paper Award—recognition for a system that unifies long‑horizon planning and robust, contact‑rich control for dual‑arm assembly.

A multi‑year arc: from sequencing in simulation to assembly in the real world

Over the past few years, we at the Autodesk Robotics Lab have been collaborating with the Computational Design and Fabrication Group at MIT, in pursuit of a consistent goal: autonomous assembly directly from CAD.

Assemble Them All introduced a physics‑based, assembly‑by‑disassembly planner that found feasible motions and sequences across thousands of complex assemblies. That work established strong computational foundations for generalizable sequence planning.

ASAP extended these ideas to physically feasible assembly sequencing with gravity and support constraints, integrating grasp and kinematics checks to make planned sequences more executable by robots. Yet, like most planners, ASAP still hit the reality gap when contact became tight and uncertainty crept in.

Fabrica is the next step: a complete dual‑arm system that starts from CAD and finishes with an assembled object on the table—no expert demonstrations, no task‑specific heuristics.

What’s new in Fabrica

1) A hierarchical, parallelizable planning stack for long horizon planning

Fabrica builds a multi‑tier plan from the CAD model and hardware and workcell specs:

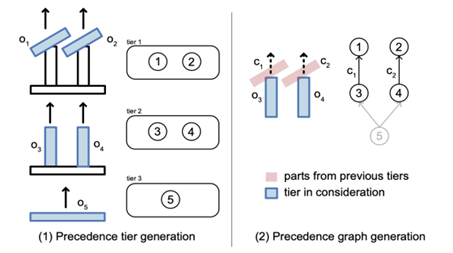

Precedence planning computes the minimal ordering constraints any collision‑free sequence must obey.

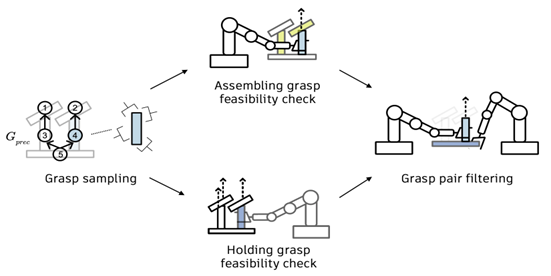

Dual‑arm grasp filtering samples candidate grasps, then filters them for stability, reachability (IK), and inter‑arm collision.

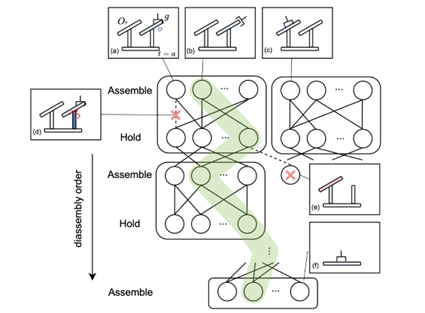

Sequence–grasp optimization jointly selects which hand assembles vs. holds at each step to stabilize the sub‑assembly.

Automated fixture generation designs pickup/holding fixtures to eliminate reorientation or regrasping.

Motion planning finds collision‑free trajectories that obey kinematic limits and promote downstream control stability.

This process is parallelizable and optimizes for stability—key to executing reliable insertions later.

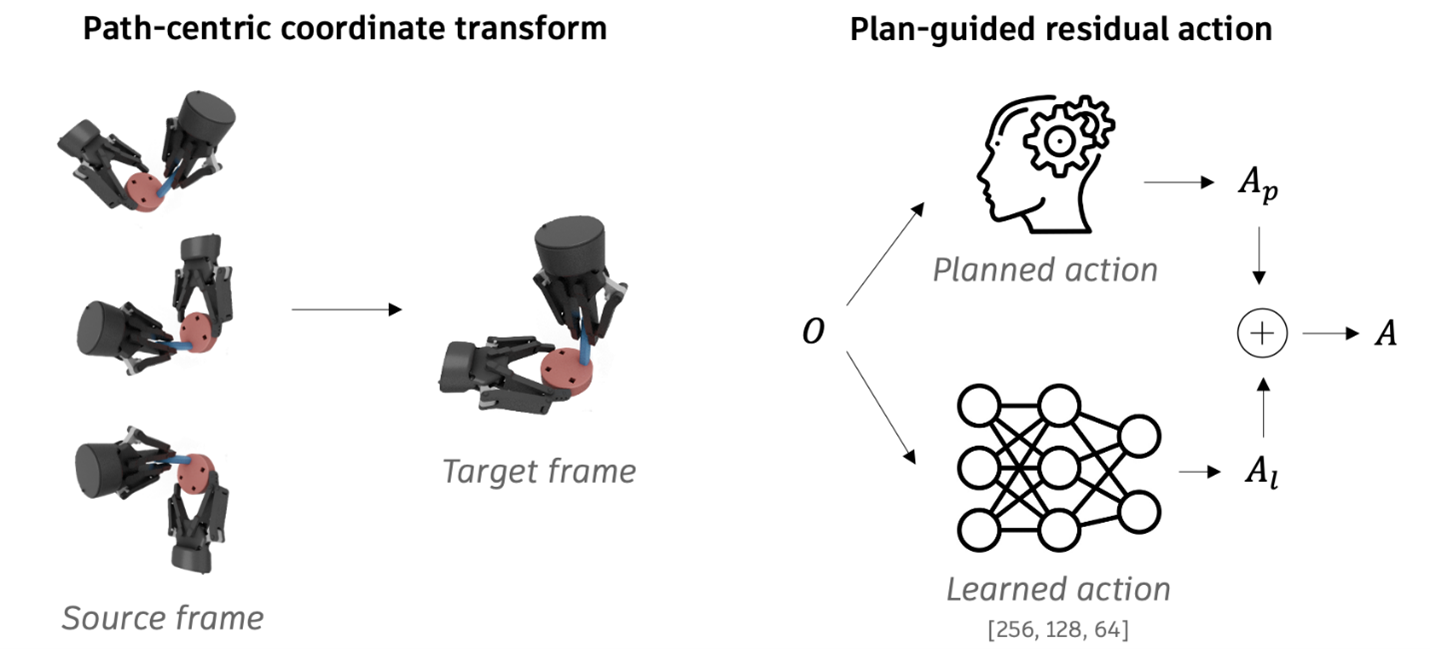

2) Lightweight, equivariant RL for contact‑rich steps

For the contact-rich insertion steps of an assembly, Fabrica switches to a generalist RL policy that:

- Uses SE(3)‑equivariant representations to generalize across object geometries, orientations, and grasp poses.

- Predicts residual actions on top of the planned motion—treating the planner’s path as guidance rather than gospel.

- Is trained across many assemblies and zero‑shot transferred to new objects in the real world.

Results at a glance

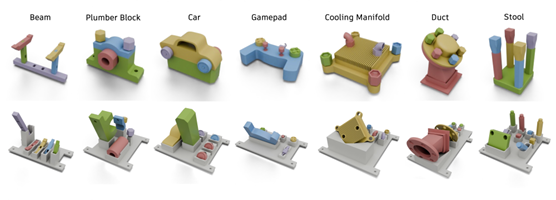

- Benchmarks: We introduce seven multi‑part assemblies (5–9 parts) spanning everyday and industrial forms—e.g., a stool, duct, gamepad shell, cooling manifold, and more—to cover different geometries and assembly strategies.

- Zero‑shot transfer: Generalist RL policies trained across multiple assemblies transfer to unseen objects with performance comparable to per‑object specialists.

- Robust execution: In real‑world experiments, Fabrica’s policies achieve around 80% success at the step level across contact‑rich insertions, enabling full multi‑step assemblies on standard dual‑arm hardware.

- Recognition: CoRL 2025 honored Fabrica with a Best Paper Award (one of two), citing its contribution to generalizable, real‑world, multi‑part assembly.

Why this matters

Modern manufacturing increasingly needs flexible, small‑batch production—new products every week, not every year. Traditional automation struggles here because it relies on manually programmed sequences, specialized setup, and brittle controllers.

Fabrica shows a different path:

- Design‑to‑robotics: Start from the CAD you already have.

- Plan globally: Compute offline precedence, grasps, and motions that make sense over the entire assembly—not just a single part insertion.

- Adapt locally: When real‑world contact physics is involved, switch to adaptive, learned skills that can correct misalignment and uncertainty on the fly.

Conclusion

We built Fabrica to bring us closer to truly autonomous robotic assembly. The system combines long-horizon hierarchical planning with flexible, learned control policies—allowing a dual-arm robot to handle complex multi-part assemblies with remarkable adaptability. Fabrica is the first to show consistent, generalizable success across real-world assemblies—an exciting milestone toward the future of factory automation.

Get in touch

Have we piqued your interest? Get in touch if you’d like to learn more about Autodesk Research, our projects, people, and potential collaboration opportunities

Contact us