No Formwork, No Steel: 3D-Printing a Greener Floor Slab

Floors are among the most material-intensive parts of a building, and some of the least optimized. They’re heavy, labor-hungry, and full of carbon-intensive cement and steel. Together with Additive Tectonics, we’ve been exploring a new approach: 3D-printed stay-in-place formwork, natural-fiber reinforcement, and low-carbon geopolymer concrete.

Join us in the manufacturing lab with Additive Tectonics to watch the full story.

Why Rethink the Floor Slab?

Conventional concrete floors have three major drawbacks:

- Formwork waste: The temporary formwork needs to be stripped and is often discarded after a single use.

- Material inefficiency: Flat slabs don’t take advantage of geometry to save weight.

- High carbon cost: Cement alone accounts for ~8% of global CO₂ emissions; steel adds another ~7–9%.

Autodesk Research x Additive Tectonics

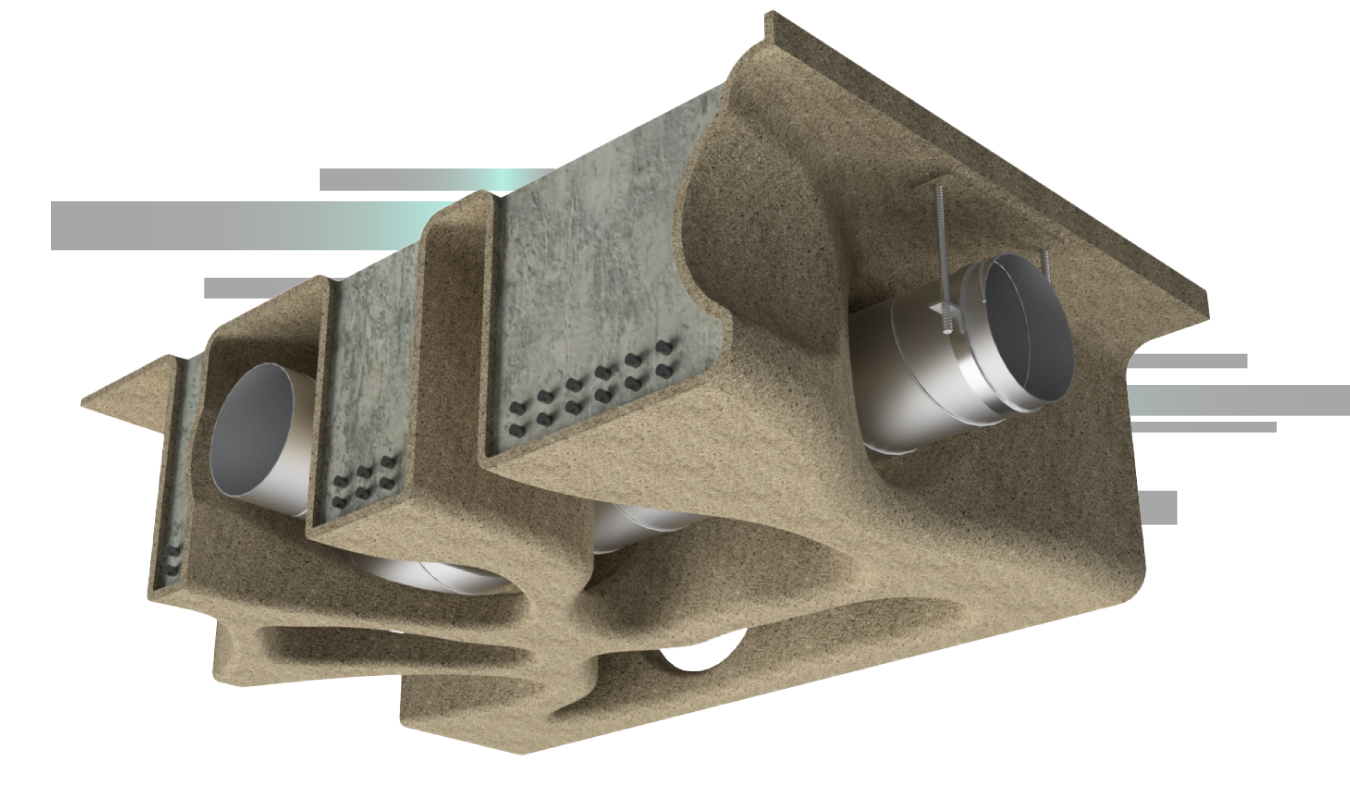

Additive Tectonics specializes in large-scale architectural 3D printing, using Selective Cement Activation (SCA), a particle-bed additive manufacturing method that selectively binds a dry mineral powder layer-by-layer. This allows for complex, high-resolution, and structurally functional shapes to be produced.

At Autodesk Research, we look for bold ways to solve challenges facing the industries we serve. Teaming up with research partner Additive Tectonics was a natural fit: their process demanded a new design mindset, and our tools could help push its potential. Together, we explored how to combine their manufacturing expertise with our design and simulation capabilities to reimagine structural building elements.

The Opportunity

We saw the chance to rethink every layer of the floor slab, starting with:

The formwork: Instead of temporary wooden formwork that’s stripped and discarded, we used Additive Tectonics’ econitWood, an upcycled wood-mineral composite that locks in biogenic carbon and works with their SCA printing technology. Using Autodesk Inventor Nastran, we optimized the geometry to remove excess material and reinforce only where needed, producing a ribbed form that follows the slab’s load paths.

The reinforcement: Rather than rigid and carbon-intensive steel rebar, we explored flexible flax fibers. Structural stress maps were translated in Dynamo into continuous winding paths, allowing robotic placement of fibers within the complex formwork geometry.

The poured “concrete”: We cast a potassium-activated geopolymer mortar, which bonded seamlessly to flax-fiber reinforcement. Because geopolymers typically don’t pair well with steel, this alternative was a perfect match.

The result was a fully integrated approach to materials, geometry, and fabrication method, producing a lighter, stronger, and more sustainable floor slab.

Next Steps

The potential is clear: less waste, less carbon, more integrated function, and a new role for 3D printing in structural floors. With new design and simulation tools working alongside Additive Tectonics’ manufacturing process, this approach is ready to scale. Future iterations could embed space for building services and attachment points directly into the slab, removing the need for a separate suspended ceiling.

Additive Tectonics will continue refining and deploying the system. We’re eager to see this technology in real projects, and what radical new geometries can be realized next!

Get in touch

Have we piqued your interest? Get in touch if you’d like to learn more about Autodesk Research, our projects, people, and potential collaboration opportunities

Contact us